Effective failure mode effect analysis (FMEA)

Learn how failure mode effect analysis can help your organisation to mitigate risk

What is failure mode effect analysis?

Using the Failure Mode and Effect Analysis (FMEA) technique will help to drive improvement in your supply chain. The methodology is now also used in risk management and service industries. It’s used as a structured method of identifying failures in a process and quantifying the effect of these on the overall success of the operation. There are two aspects of failure mode effect analysis:

Failure mode

Is the way in which something could fail. Such as errors or defects in a process or product. These errors can be potential or actual.Effects analysis

Is the process of studying the consequences of the discovered failures.What are the principles of failure mode effect analysis?

The FMEA process is conducted in a step-by-step way. Each step builds on the previous one as you work through the analysis process. FMEA is done in seven stages, each one carefully designed to make the analysis quick and effective: The steps are listed below:

- Assemble FMEA team and review the process in question for potential failures

- Determine the severity ranking of each failure

- Determine the occurrence ranking of each failure

- Determine the detection ranking of each failure

- Assign a Risk Priority Number (RPN) and prioritise for action

- Act and review the process

- Re-rank the RPN

Each element of the process is reviewed and any potential problem area or weak links prone to failure are identified and described. These areas are then rated 1-10 within the following criteria:

- Severity:

How severe is the failure of this element likely to be? 1 = low, 10 = very severe - Occurrence:

What is the likelihood of this problem occurring? 1= low, 10 = very high - Detection:

What is the likelihood of us detecting the failure early in the process? 1 – high likelihood of early detection, 10 – high likelihood we will not detect a failure

After the scoring is complete, the three scores are multiplied together:

Severity x Occurrence x Detection – Risk Priority Number (RPN)

The RPN’s are then sorted from largest to smallest and actions are taken on the top-scoring risk to mitigate.

What is the purpose of the failure mode effective analysis?

Failure Mode and Effect Analysis (FMEA) is just one element of the Six Sigma Lean Methodology.

The Six Sigma route to quality control emerged in the 1980s as Motorola searched for a robust quantitative approach. They wanted a high variability out of their manufacturing processes to improve the reliability of their products. The term Six Sigma refers to a methodology and a culture of continuous quality improvement.

The Six Sigma goal is to squeeze out process variability until the process produces just 3.4 defects per million activities. This reduces waste and hence saves money whilst improving customer satisfaction.

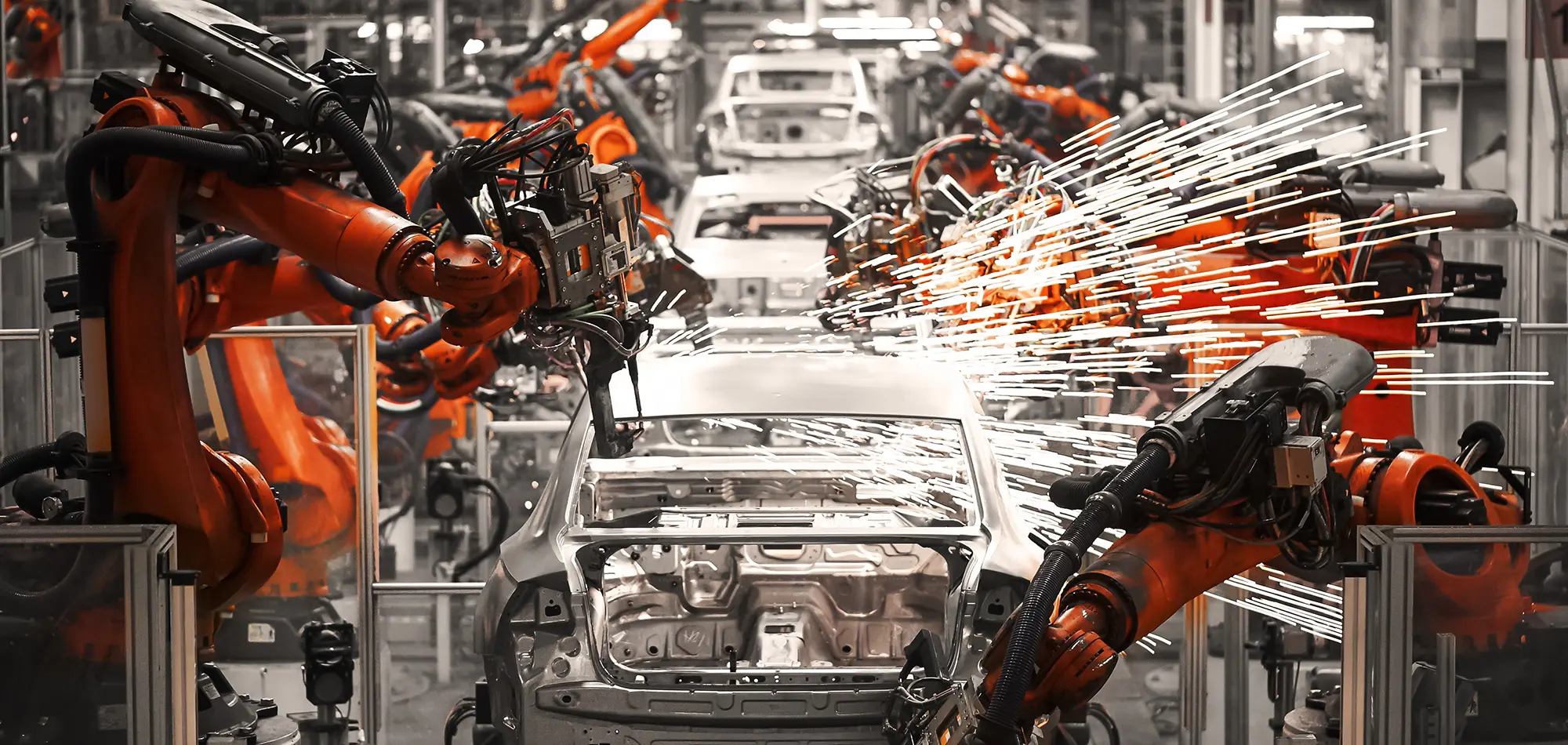

The use of FMEA techniques helps to drive improvement in manufacturing and supply chains.